On our way to climate neutrality, we want to further advance the digitalization of our production processes. For this reason, we have installed the first Beam 2C laser die cutter for corrugated packaging at our display plant in Breda. Highcon's digital creasing and laser cutting technology combines high material and process efficiency with innovative strength and positive environmental aspects.

For a new dimension of added value

Fully automated process

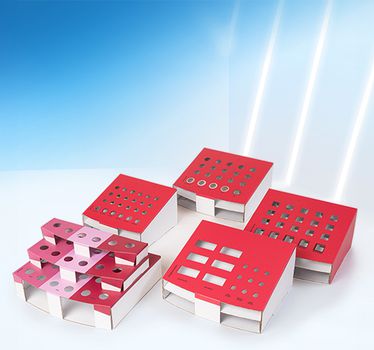

The digital laser punch replaces the conventional punching and set-up process with a fully digital workflow. The innovative technology enables a high degree of flexibility in terms of batch sizes, delivery times and changes in size or shape. The laser is able to cut even the finest or most complex patterns, offering completely new design options. The Beam 2C closes the gap between design creativity and production capability and takes digital punching and creasing to a new dimension of added value - both for us and for our customers.

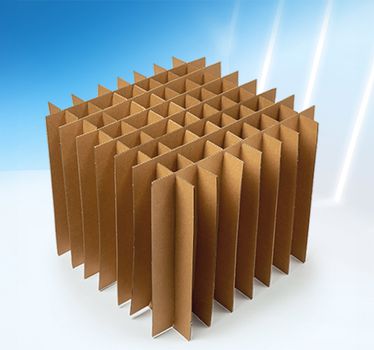

DART station and laser system

Workflow and advantages at a glance

Creasing is based on Highcon's patented DART (Digital Adhesive Rule Technology), which replaces traditional lines and channels. With Highcon's DART process, digital creases are written onto a DART film in the machine in just 15 minutes. At the touch of a button, the creasing process is then started over the DART film stretched on a cylinder.

No tools are required for the subsequent die cutting with the laser. Neither wood, metal nor rubber are used, which are required for the production of a conventional cutting die. And there is also no need for transport and storage. This saves material, costs and time.

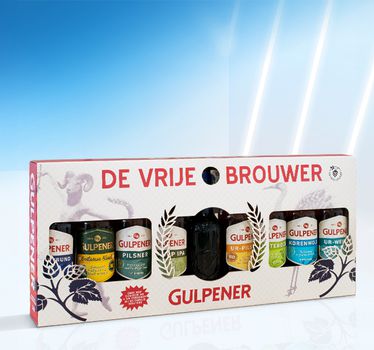

Cutting, perforating, engraving: With the Beam 2C, even the finest structures and complicated shapes can be punched out that would be impossible to achieve in any other way. This opens up completely new possibilities for designers and brands. The die cutting process is also completely contactless. The cardboard is not crushed and retains its mechanical properties better than with analog die cutting, allowing the paper's potential to be fully exploited.

Gold at the Display Superstar Awards

The creatively designed candy-shaped packaging was worth a gold award to the jury at the Display Superstar Award 2023. The detailed, three-dimensionally arranged winter landscape, which is presented through a viewing window, consists of countless filigree individual parts. Their production was only possible digitally using the BEAM 2C laser die-cutter.

TALK TO US.

We will be happy to advise you.

Hello!

My name is Jochen Drösel. My team and I are the people who make things happen at Schumacher Packaging. No matter how special your requirements are: We realize individual solutions, perfectly tailored to your needs. We look forward to hearing from you!